-

HydrationTHORZT™SSSF

HydrationTHORZT™SSSF

-

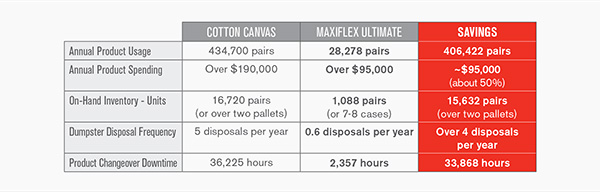

General Purpose Gloves - CoatedMaxiFlex® Ultimate™34-874

General Purpose Gloves - CoatedMaxiFlex® Ultimate™34-874

-

Cut Resistant GlovesMaxiFlex® Cut™34-8743

Cut Resistant GlovesMaxiFlex® Cut™34-8743

-

Work ApparelBisley®411W6150

Work ApparelBisley®411W6150

-

Heated ApparelBoss®300-HV100

Heated ApparelBoss®300-HV100

-

Ear PlugsPinchfit™ BioSoft™PF-1

Ear PlugsPinchfit™ BioSoft™PF-1

-

Safety HelmetsTraverse™280-HP1491RVM

Safety HelmetsTraverse™280-HP1491RVM

-

Hi-Vis Cold GearPIP®333-1740

Hi-Vis Cold GearPIP®333-1740

-

Hi-Vis Cold GearPIP®333-1766

Hi-Vis Cold GearPIP®333-1766

-

Safety HelmetsTraverse™280-HP1491RM

Safety HelmetsTraverse™280-HP1491RM

-

Hi-Vis ApparelPIP®302-0500

Hi-Vis ApparelPIP®302-0500

-

Cut Resistant GlovesMaxiCut® Ultra™44-3745

Cut Resistant GlovesMaxiCut® Ultra™44-3745