“If you can’t get the disposable PPE that you need, do you simply not open your facility?” Kirby asks. “That’s not a realistic option for most companies.”

The reusable gloves have additional advantages to being cost-effective over disposable gloves, says PIP:

- With fewer gloves on inventory, inventory space isn’t as tied up as it would be for disposable gloves.

- A breathable polyester glove liner keeps your hands dry, while the glove’s polyurethane coating on contact areas protects against shared surface contact.

- A proper fit increases comfort and reduces hand fatigue.

- Reusable gloves mean you avoid exponentially rising prices due to pandemic-related demand.

- Lower waste and pollution implications.

It’s worth remembering that disposable nitrile gloves are not always the best option for manufacturing settings, as they are not designed to be as long-lasting or as long-lasting or as protective with occupational hazards.

They are made of a thin layer of rubber, typically for one use. Thicker rubber gloves may appear more durable, but like disposable gloves, they can be uncomfortable when worn for long periods of time, making your hands sweat, and so are more susceptible to harboring germs and bacteria.

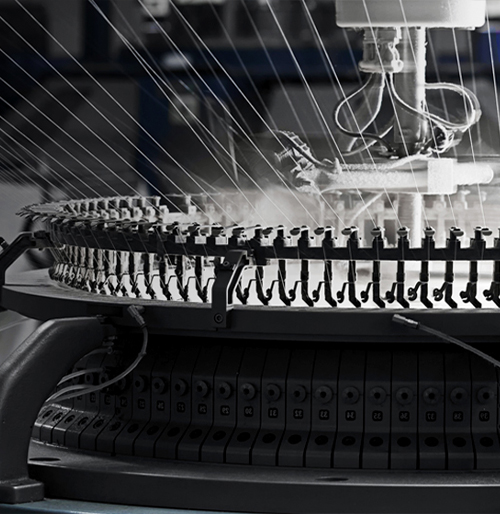

PIP’s coated seamless knit gloves are form-fitting and have breathable liners. The contact part of the hand is coated with a polymer rubber or polyurethane, making it ideal for preventing direct contact with shared surfaces or items.

Protection Across Many Sectors

Founded in 1984 by Joe Milot and Wellson Tao, PIP has since grown into a safety products supplier with some $650 million in annual sales. The company now serves customers in sectors such as industrial, construction, food safety, electrical safety and welding safety.

Under the current “new normal” environment, with demand high and supply of disposable PPE low, PIP has differentiated itself by providing an alternative to PPE: protective work gloves that can be washed and reused.

“There is not just a supply issue, but also a scarcity of material and labor that has meant the cost of disposable garments and gloves has shot up exponentially,” Kirby says.

The company offers 11,000 products in 15 product categories, from hand protection to respiratory safety, and has a strong commitment to research and development, with a team of over 60 people dedicated to product development and new technologies. The company has developed over 100 new products in the last 12 months.

PIP’s go-to-market strategy is intimately linked with its distributor-partners. The company does not sell directly to customers but instead works with distributors to sell its products, working on training and doing joint calls. PIP differentiates itself by a combination of product and value-added service, Kirby says.

“Our salespeople focus on training because we know that is the No. 1 need for our distributor partners,” she adds.

“Close to home, we manufacture high cut-resistant gloves and sleeves, hearing protection, hard hats, face shields and hearing protective muffs,” Kirby says. “At the same time, we have long-standing partner factories around the world making key products for us. We have strong product and R&D teams in the USA, Canada and Asia who work with these partner factories to develop new technologies and ensure compliance specifications are met.”

How are you managing to meet your PPE needs? Are you purchasing reusable PPE to save costs?